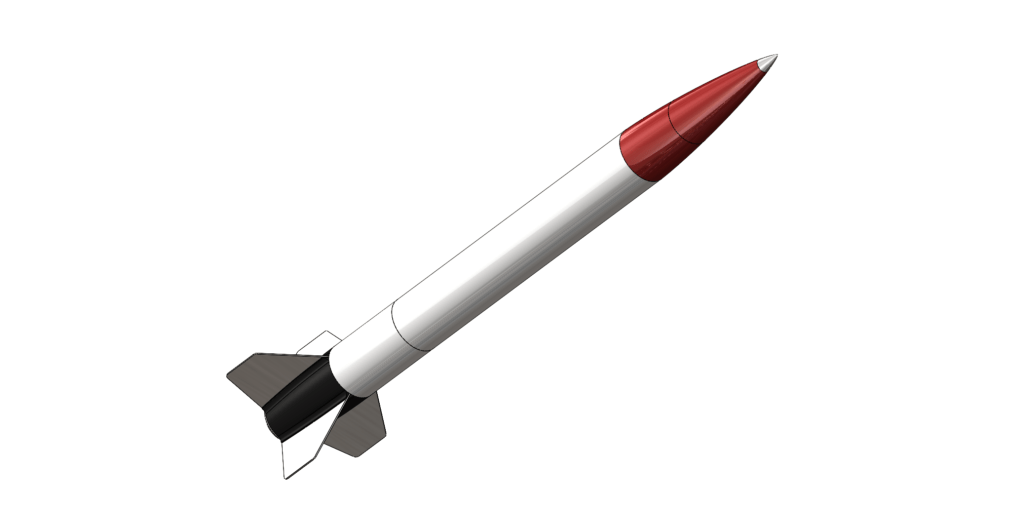

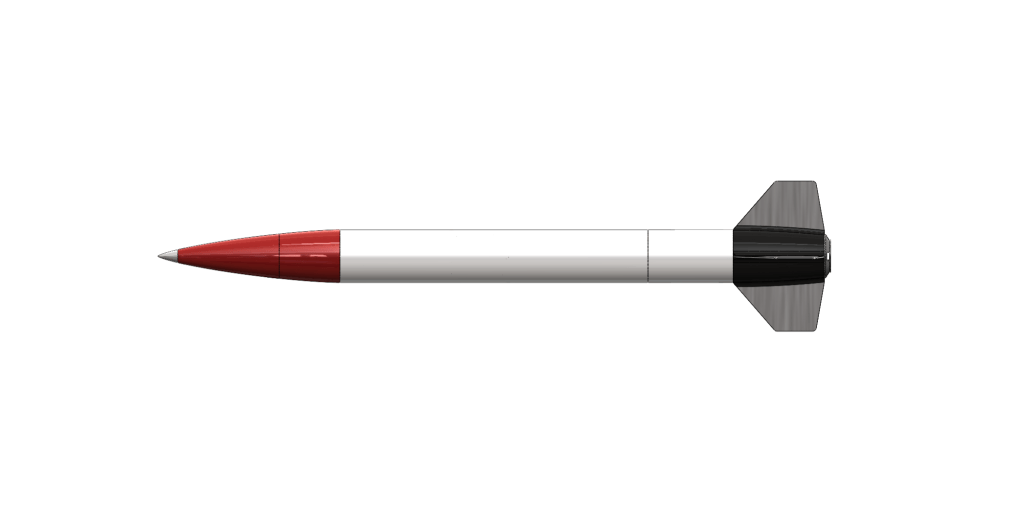

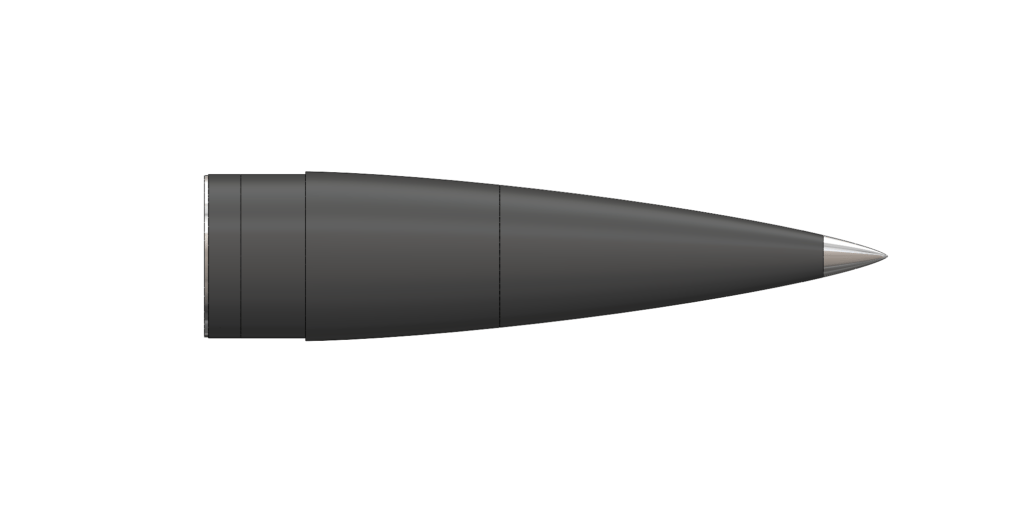

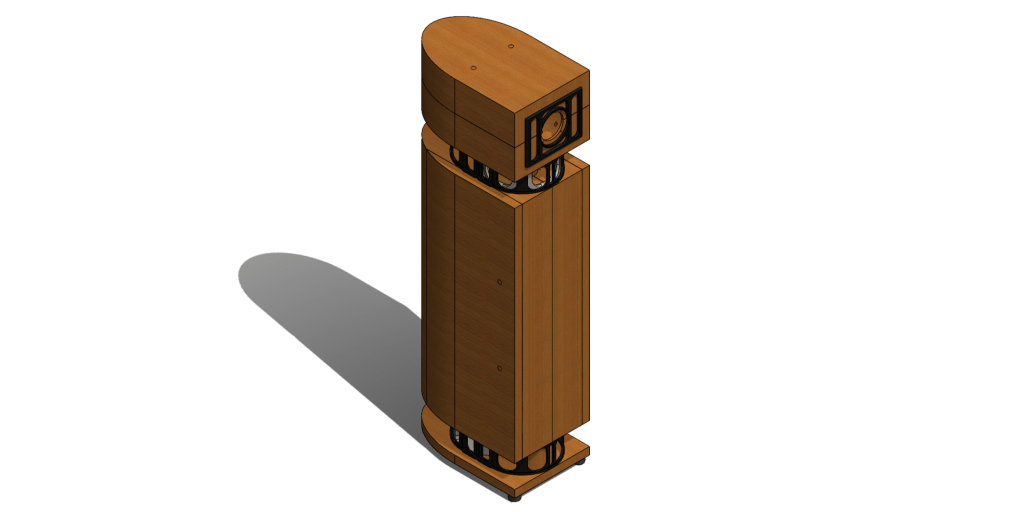

Skoden is my Engineering Design Teams Liquid Rocket project. I have been handling the Airframe of this project, including the nosecone, avionics, fincan, and engine chamber.

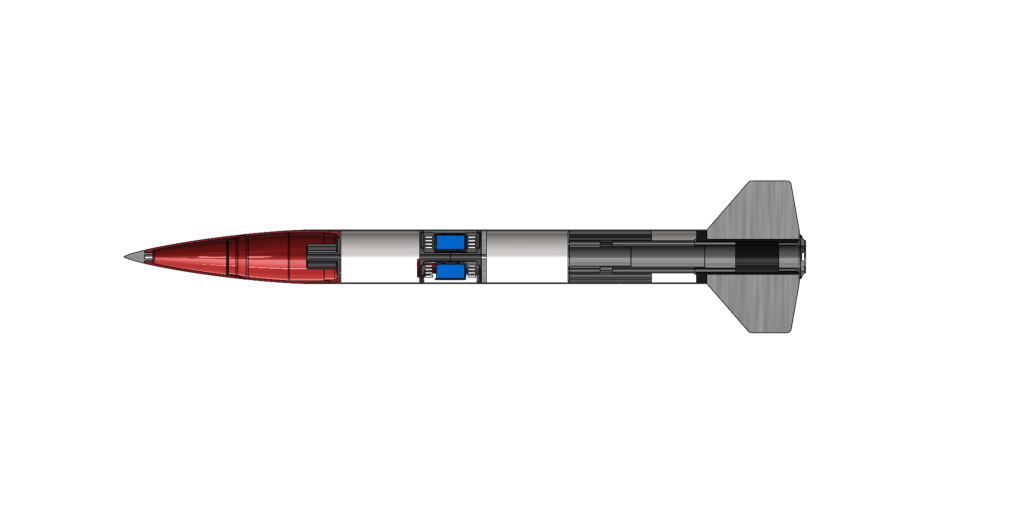

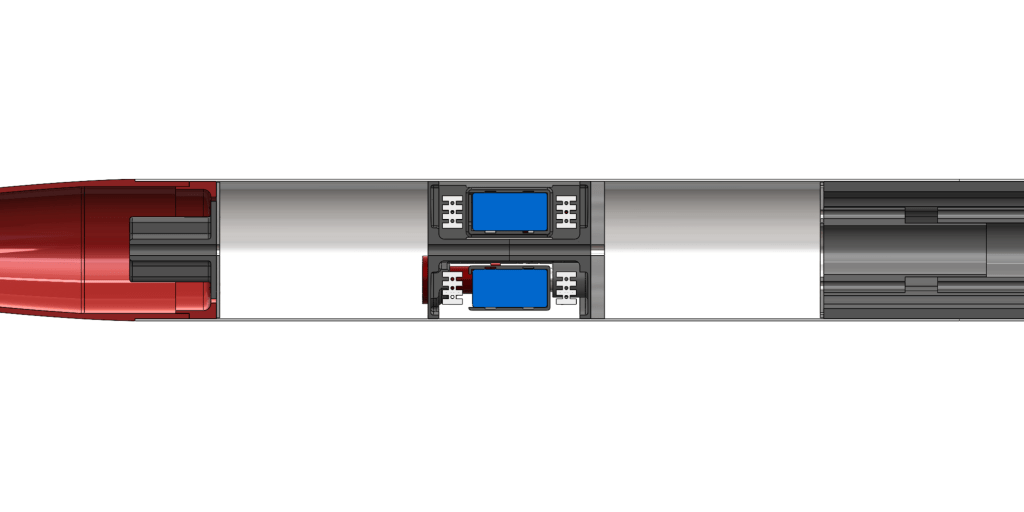

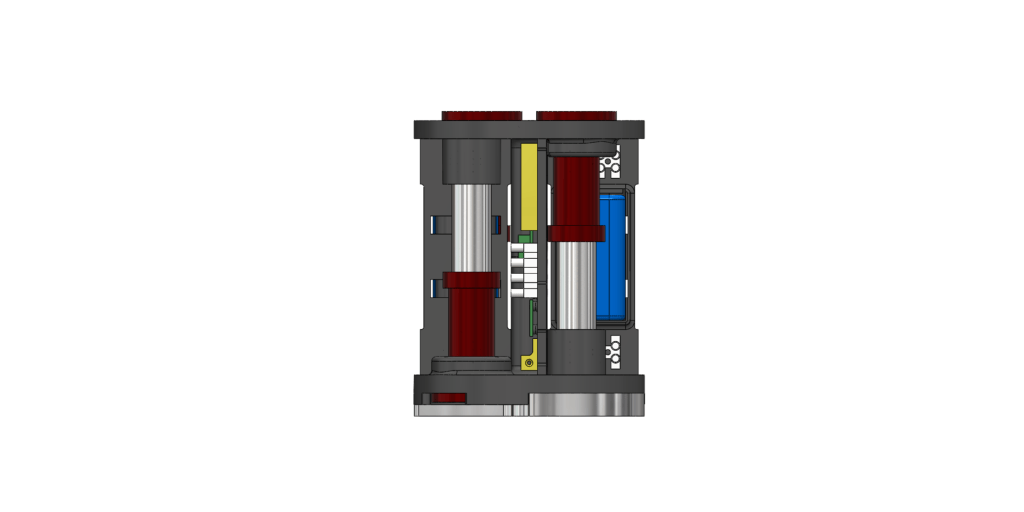

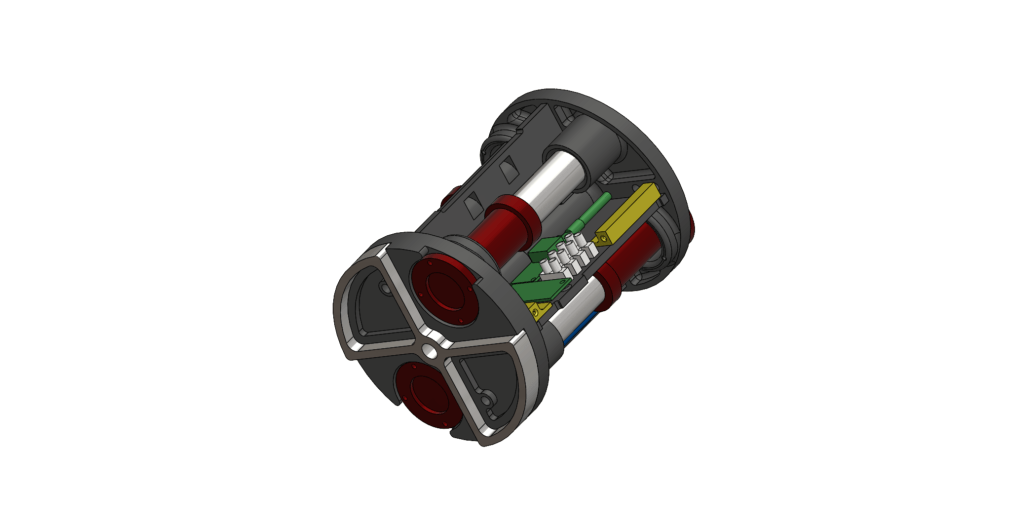

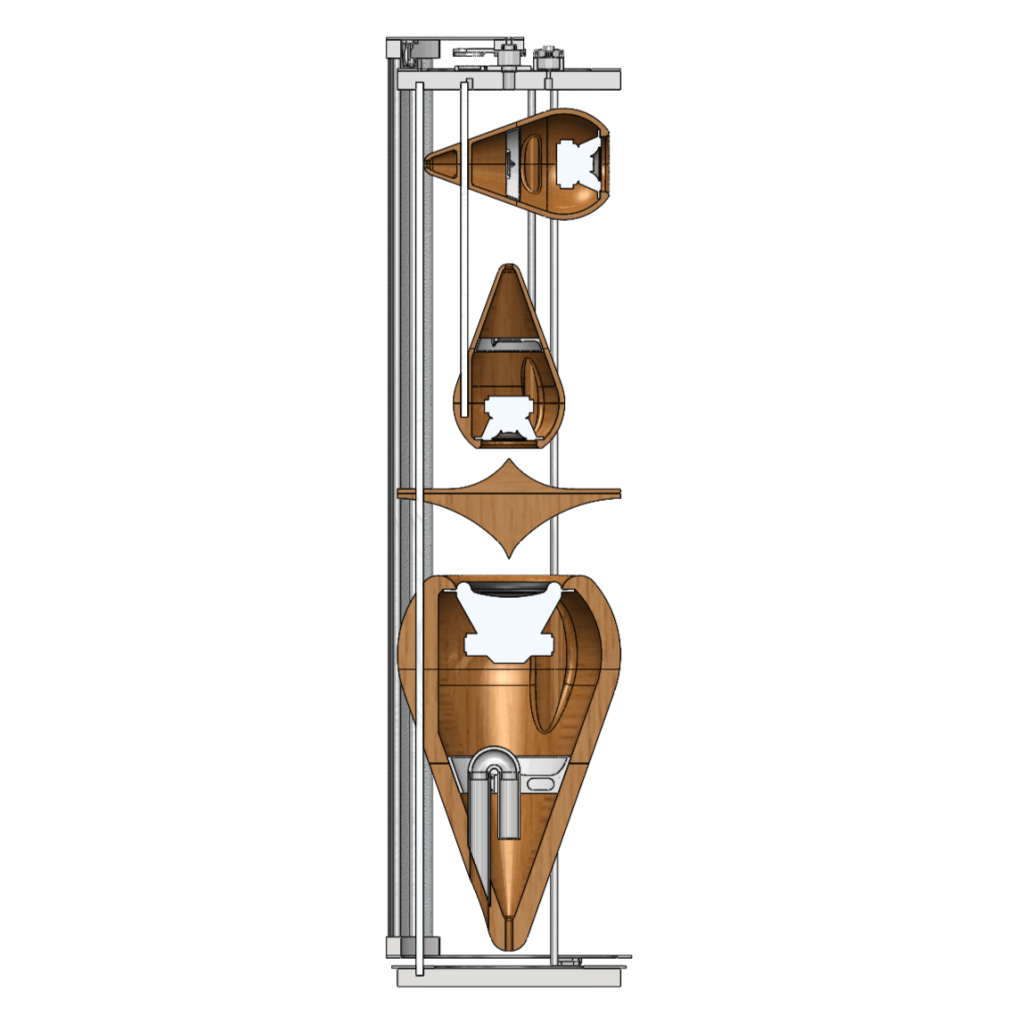

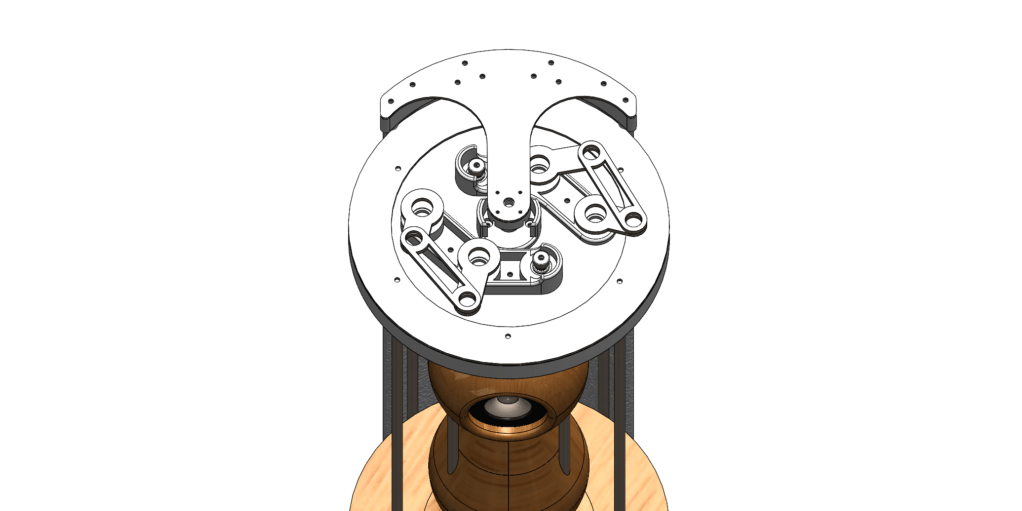

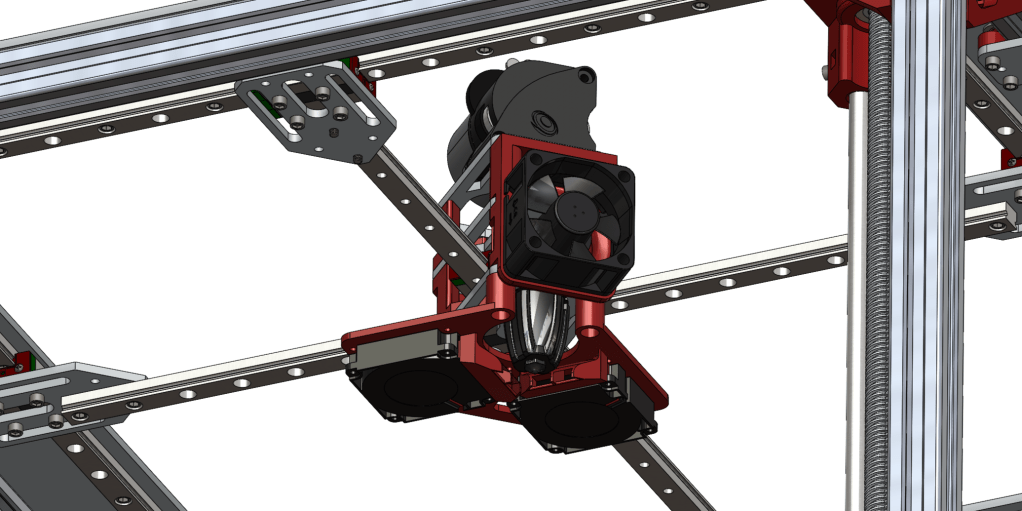

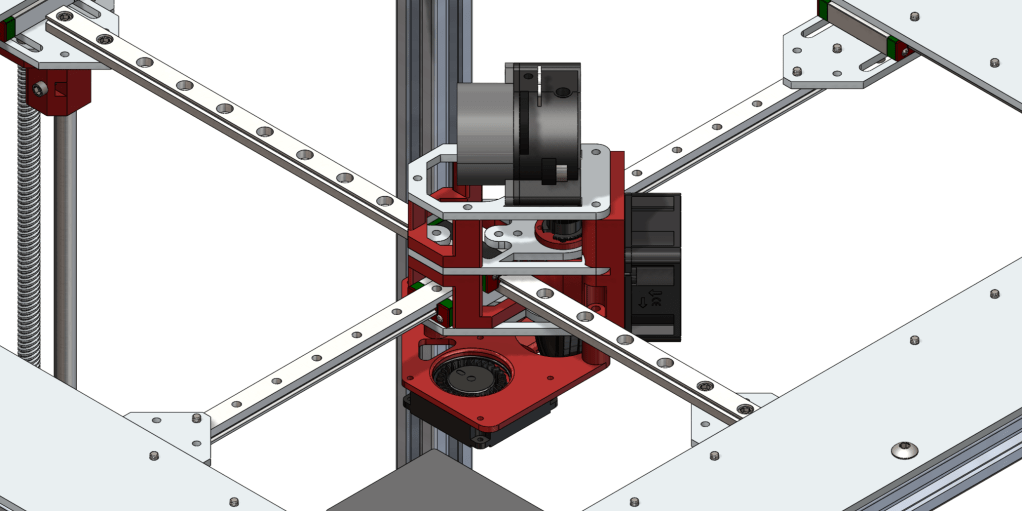

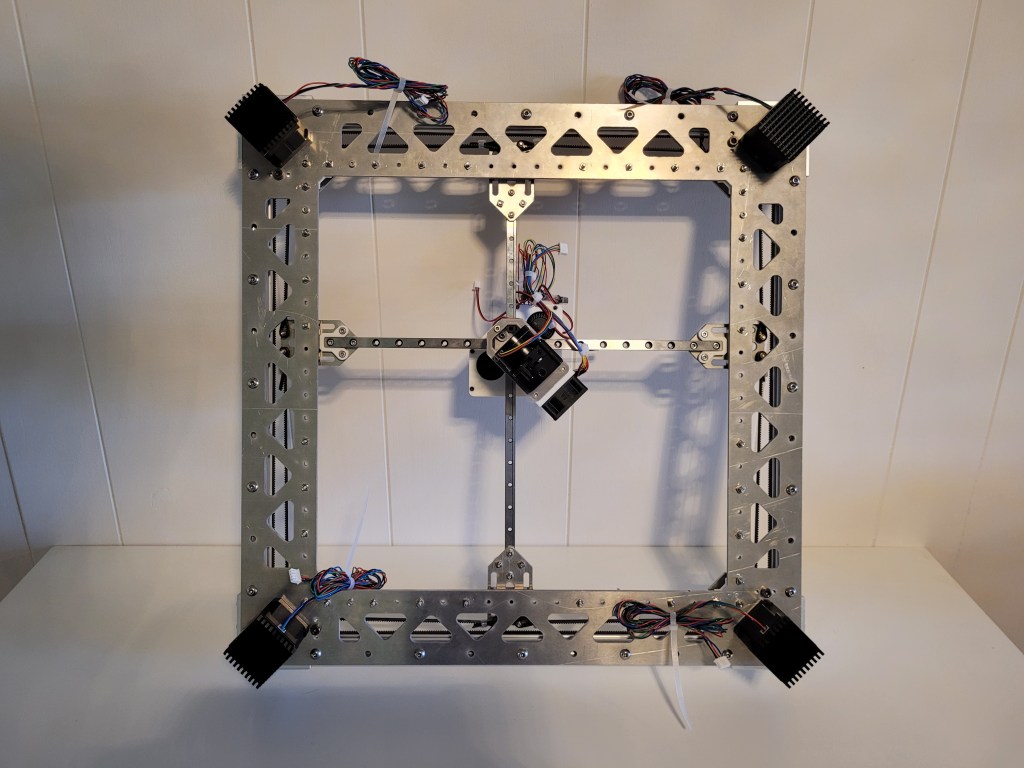

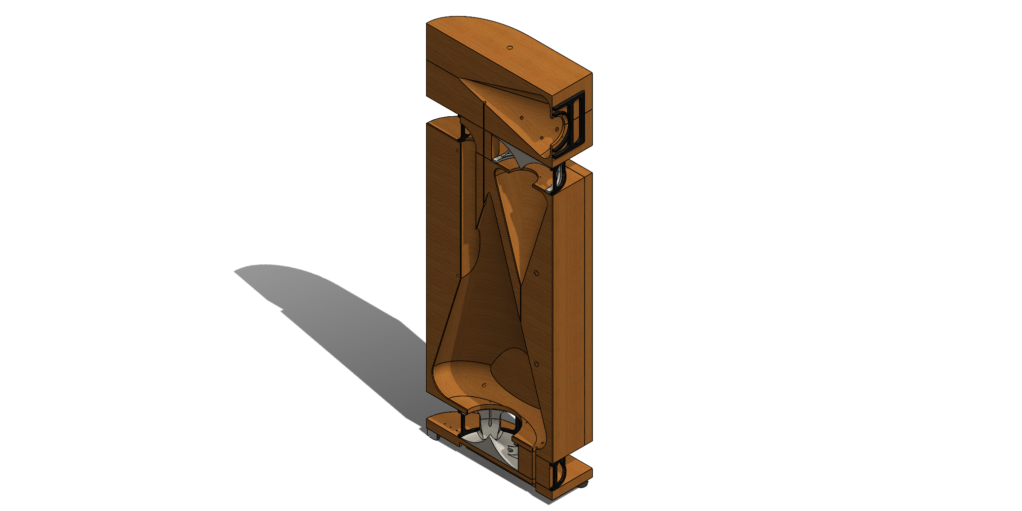

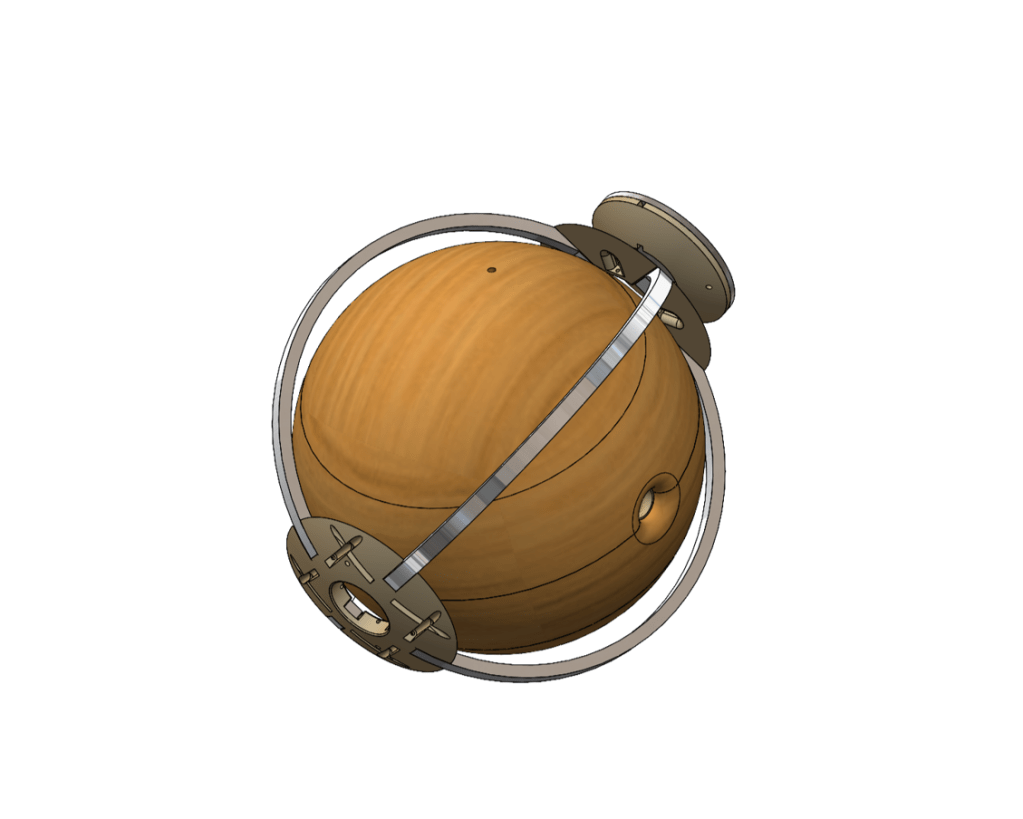

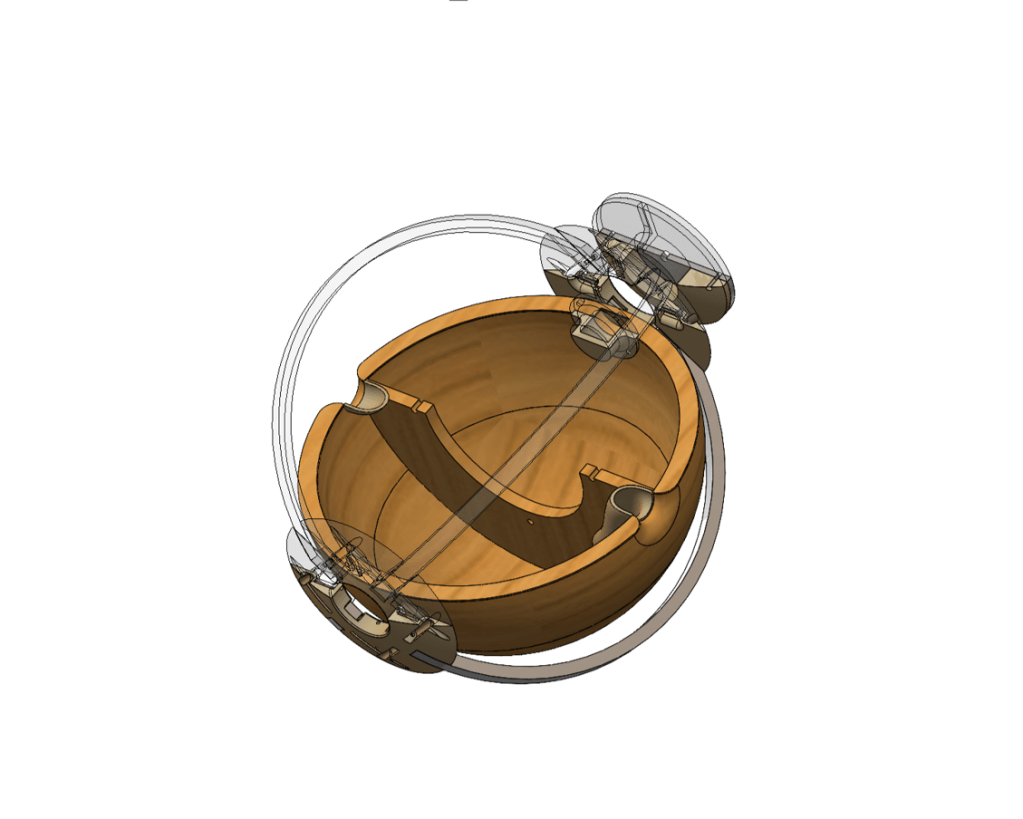

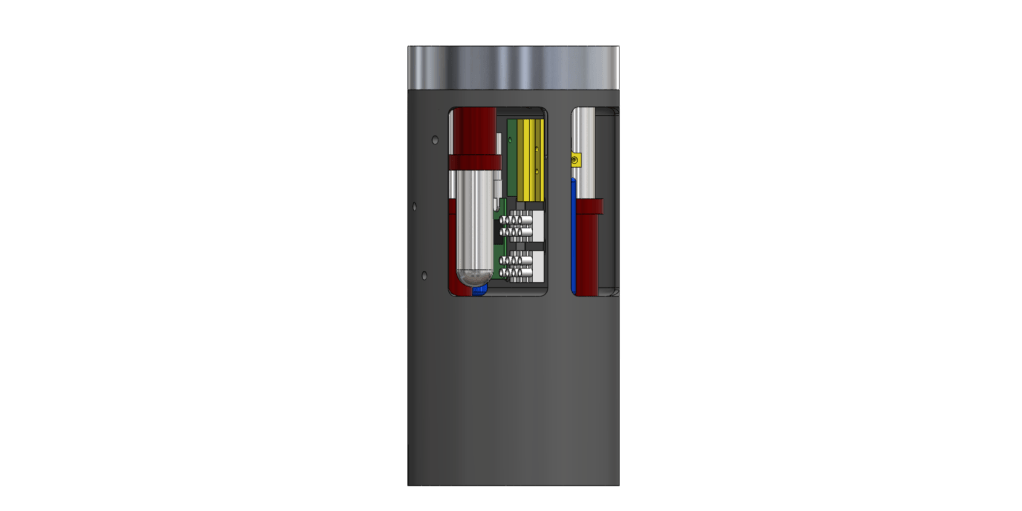

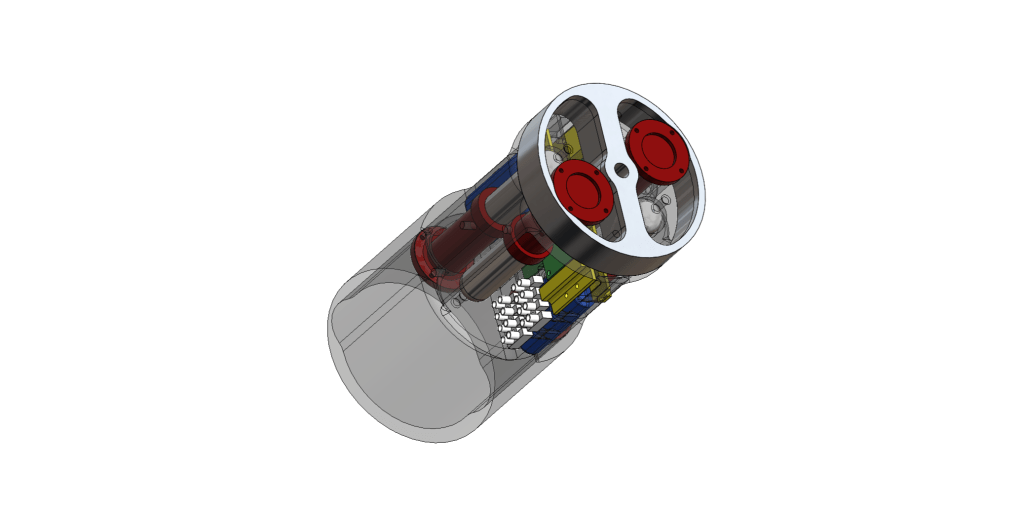

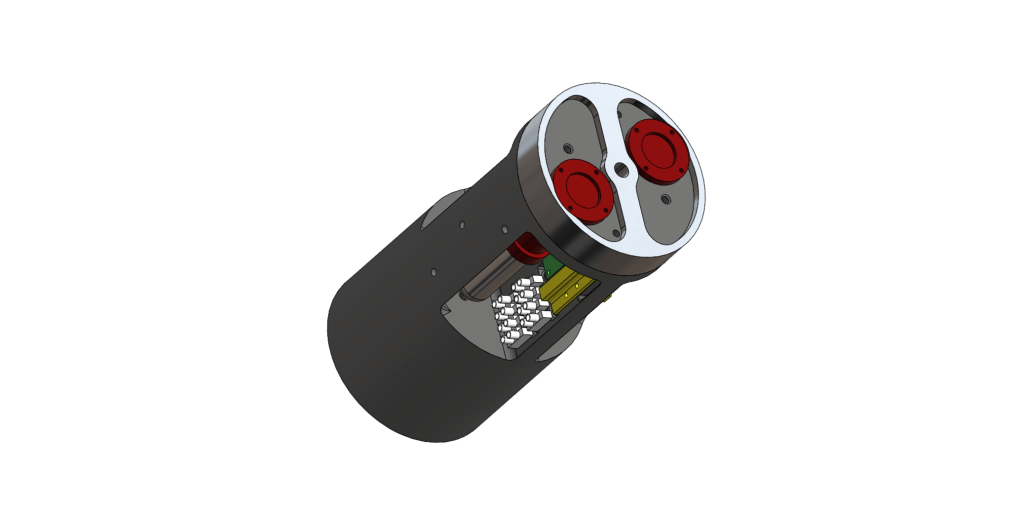

The avionics bay was a challenge to design due to the 5inch ID of the bodytube — half an inch less and our avionics would have to be distributed over much more length, forcing the rocket to become overstable due to increased length (notice below how close the red CO2 ejectors are to the support ring)

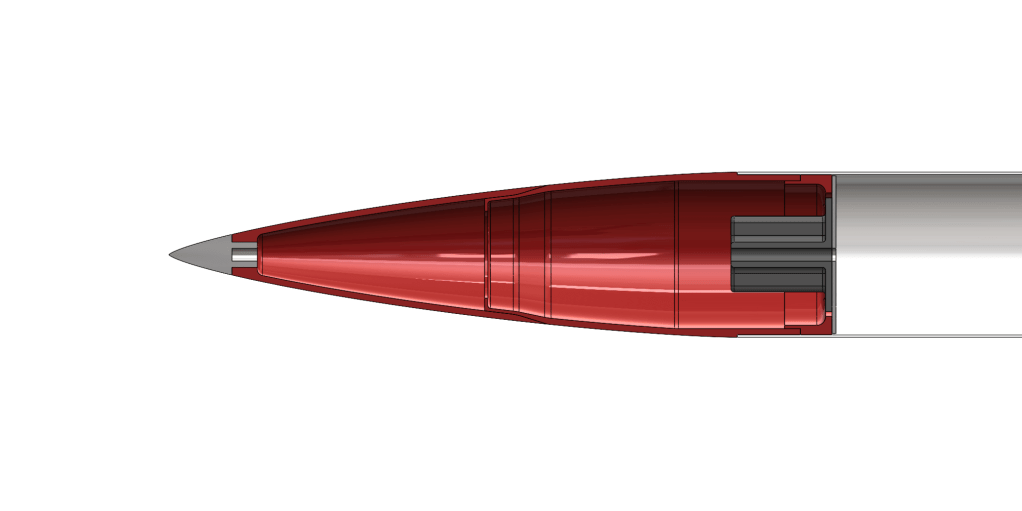

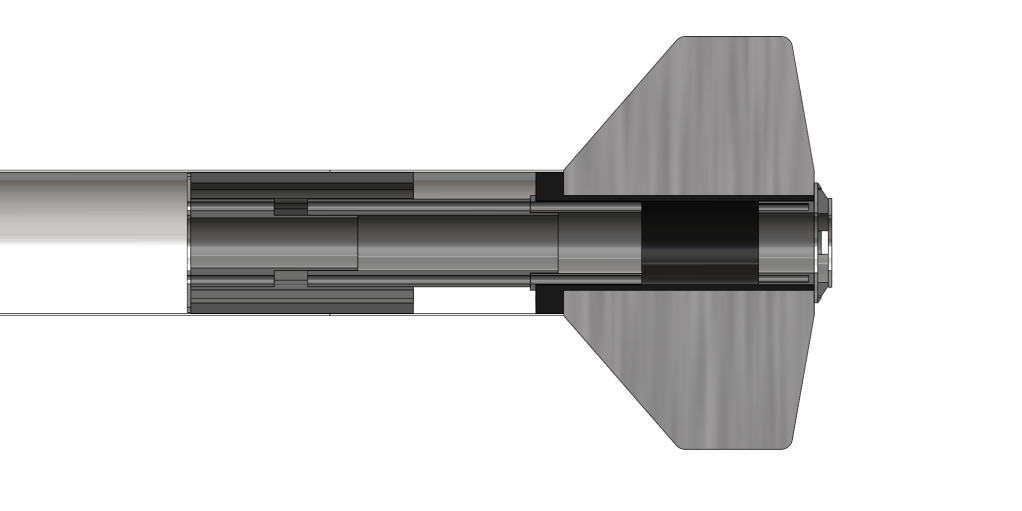

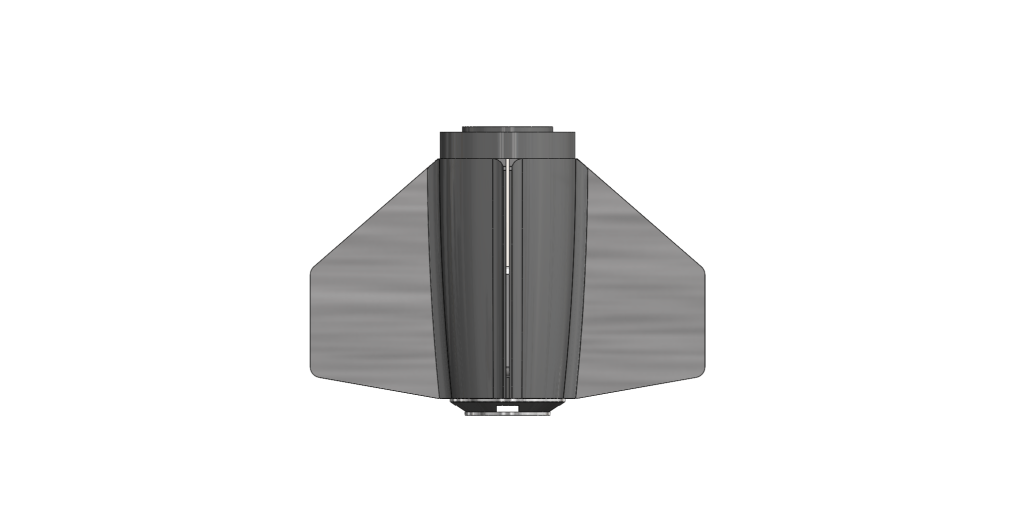

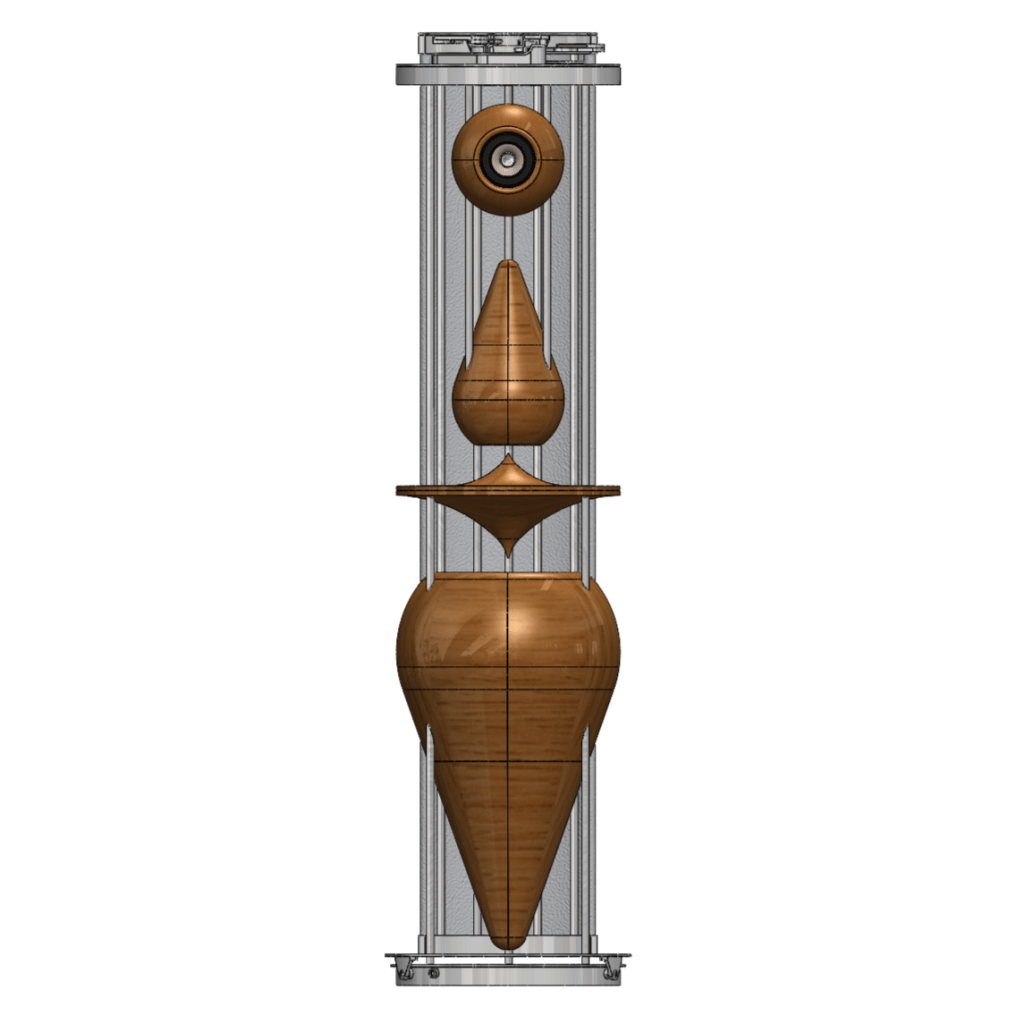

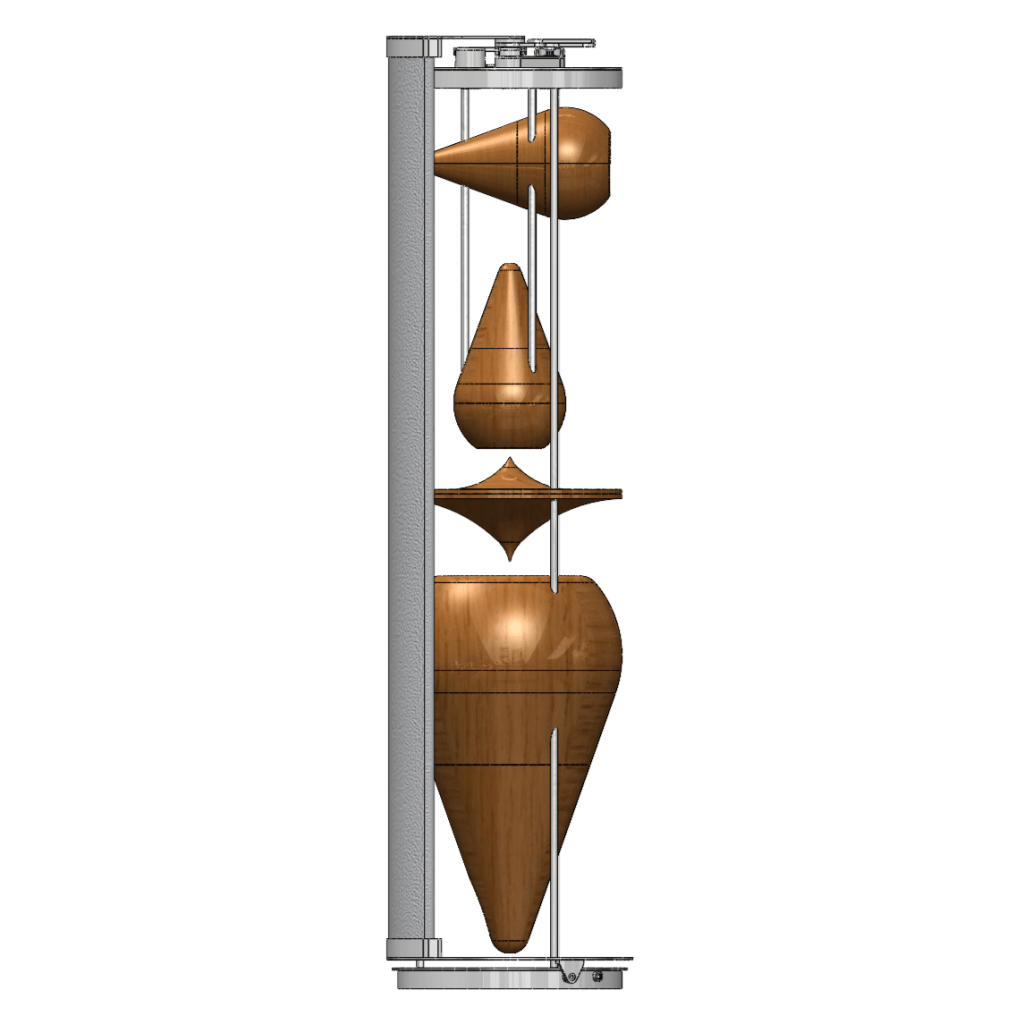

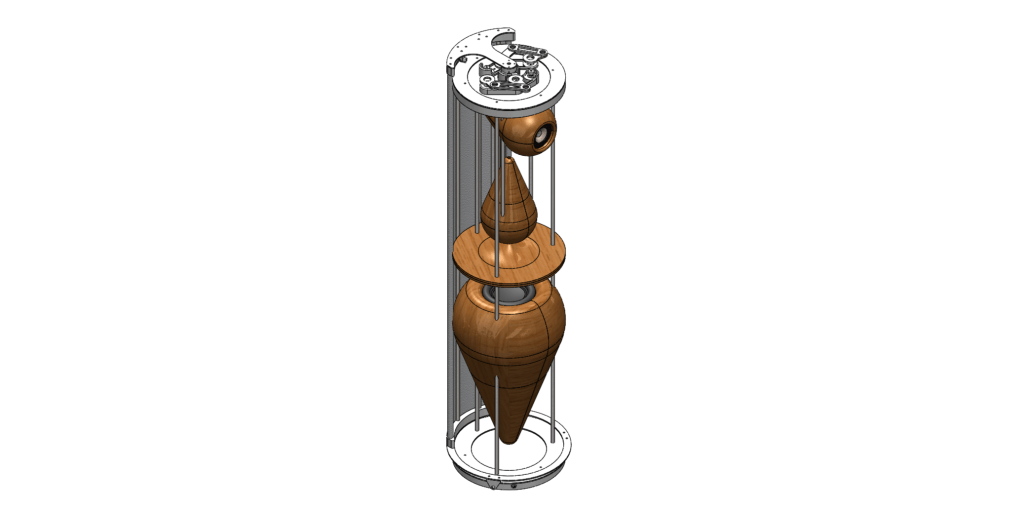

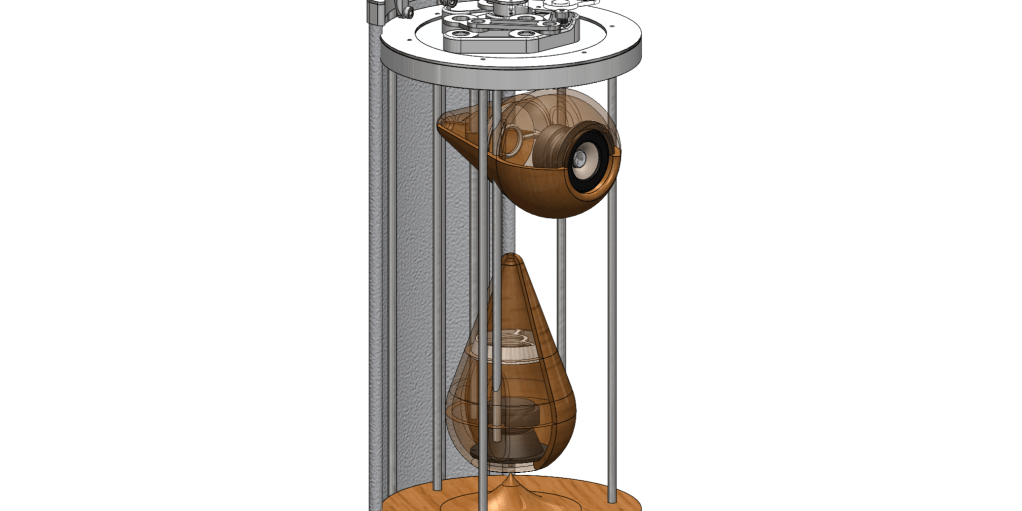

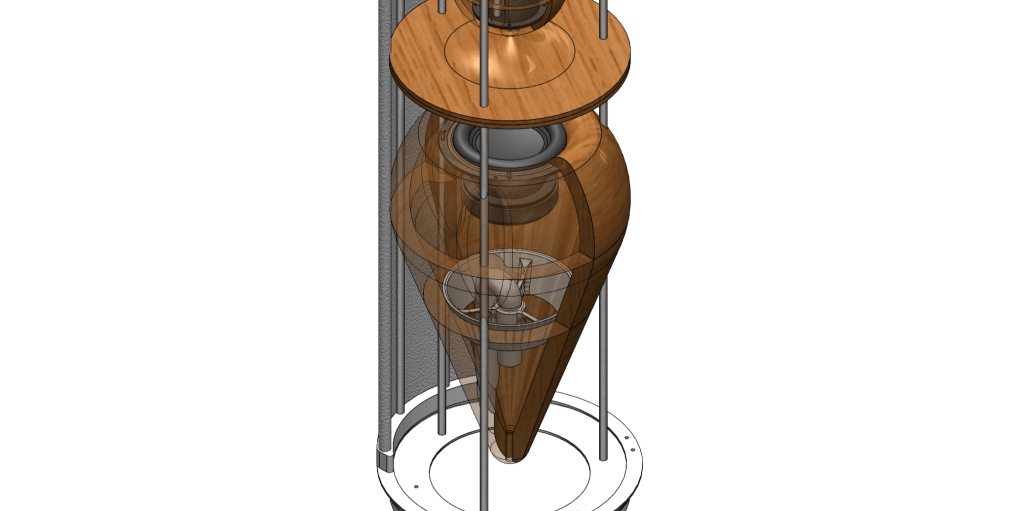

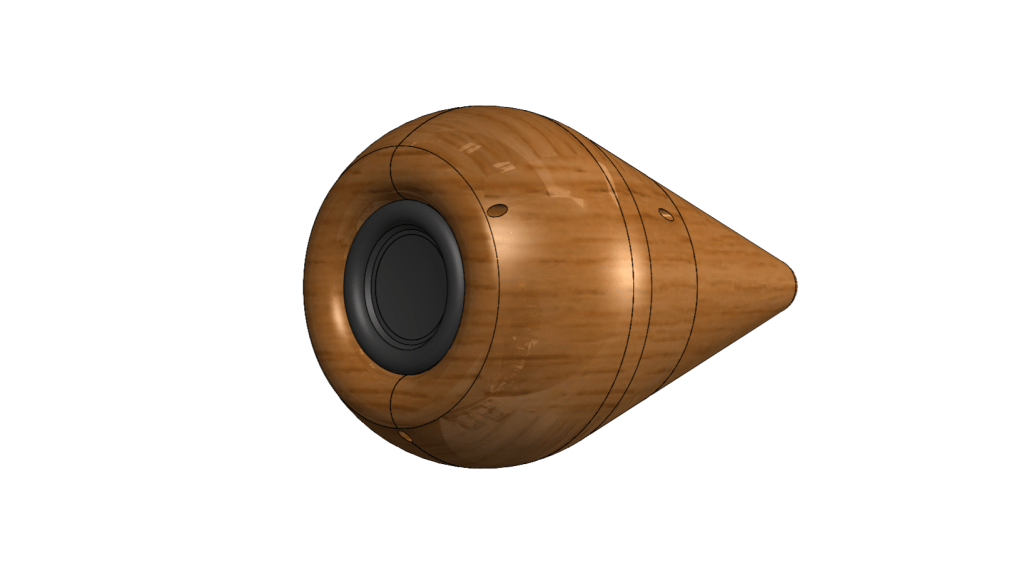

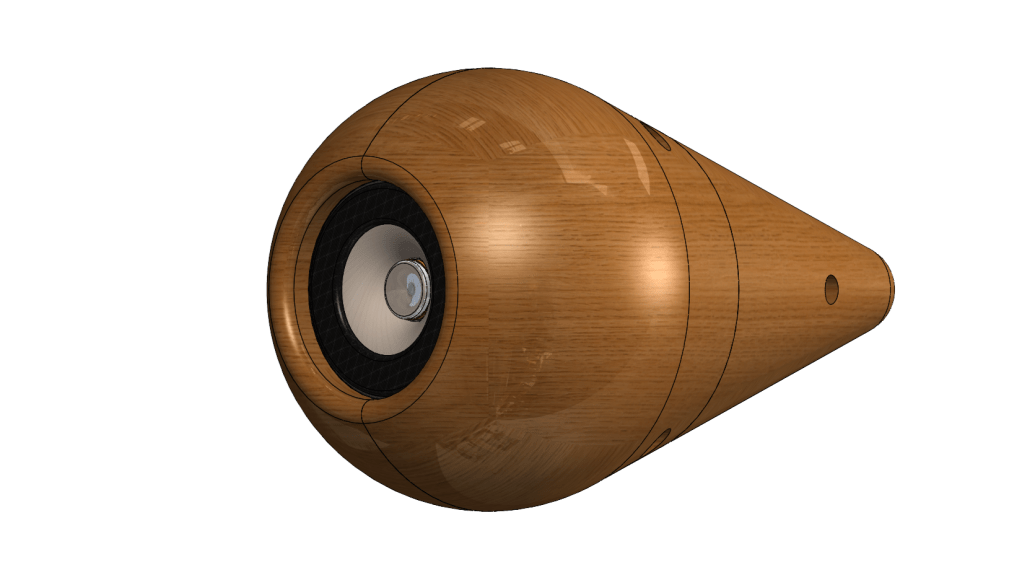

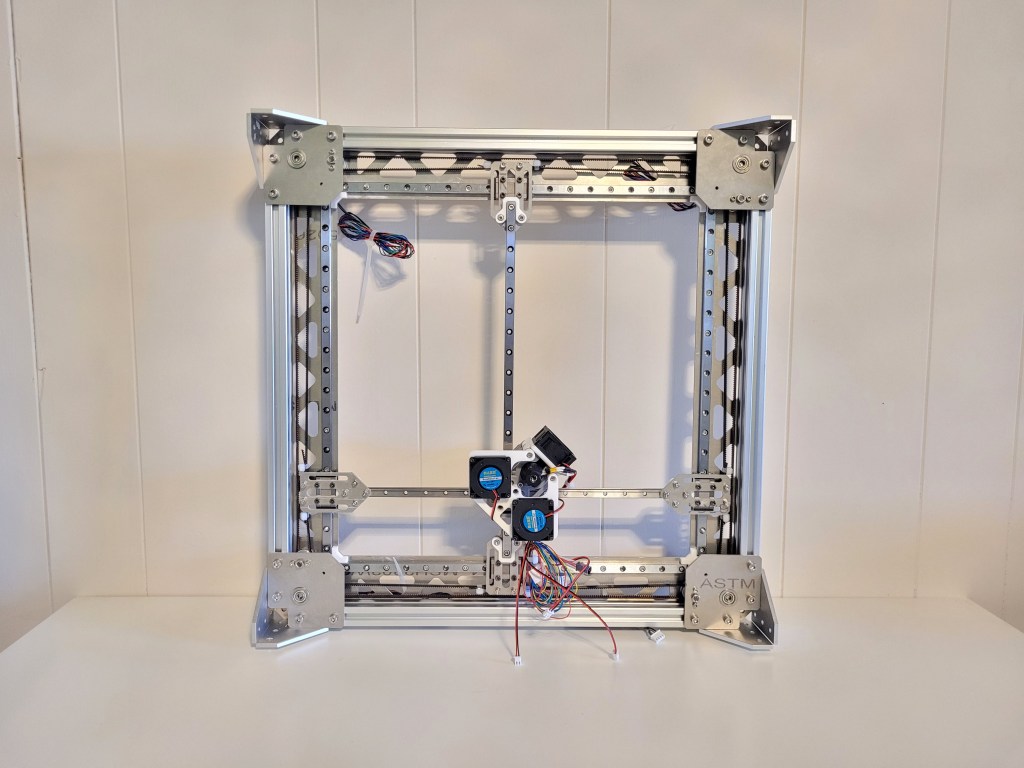

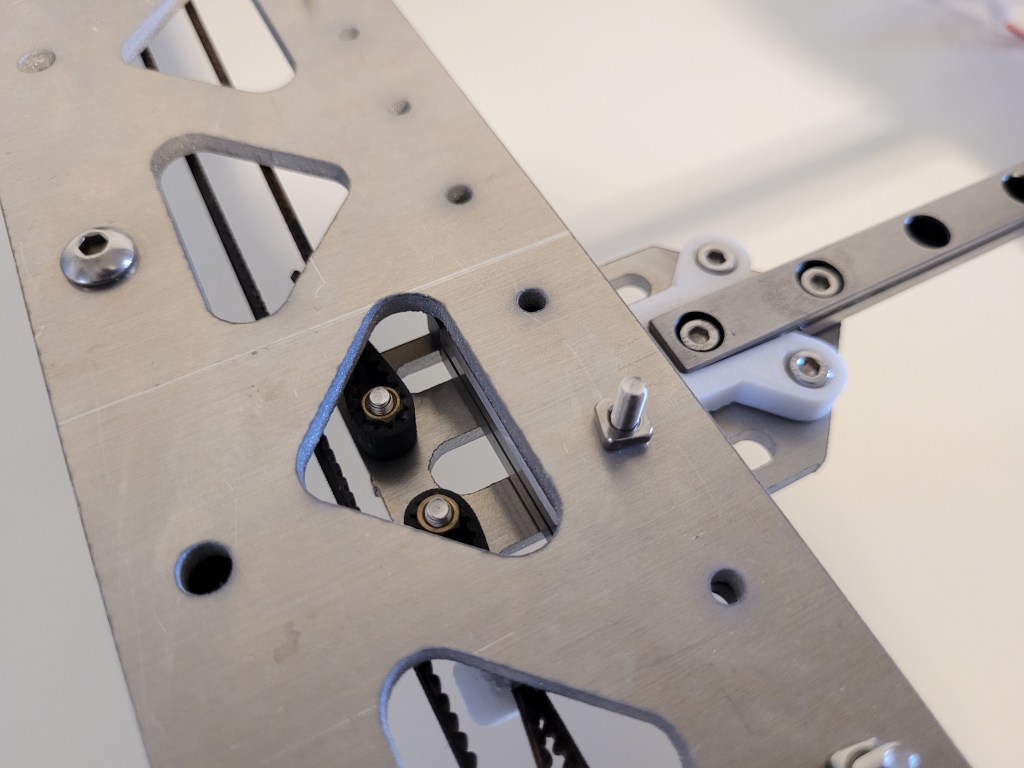

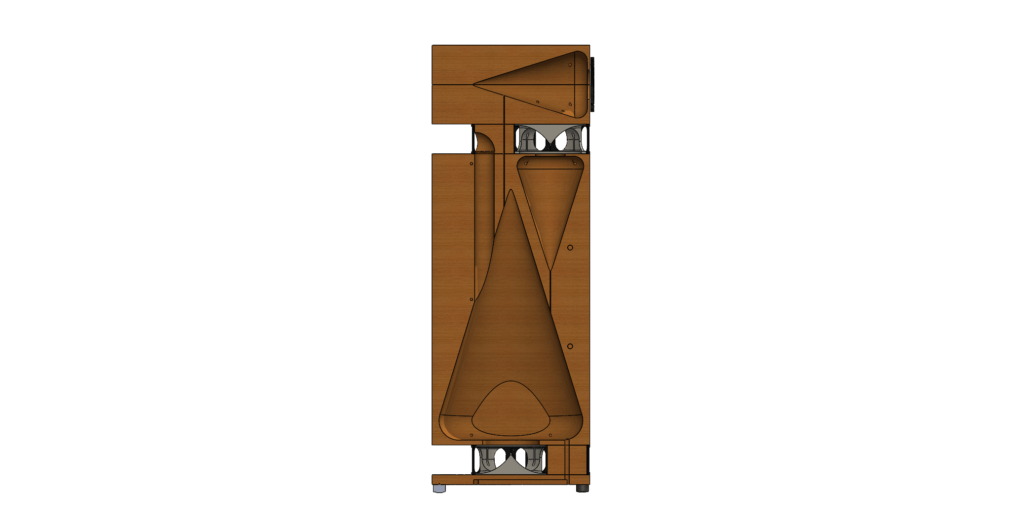

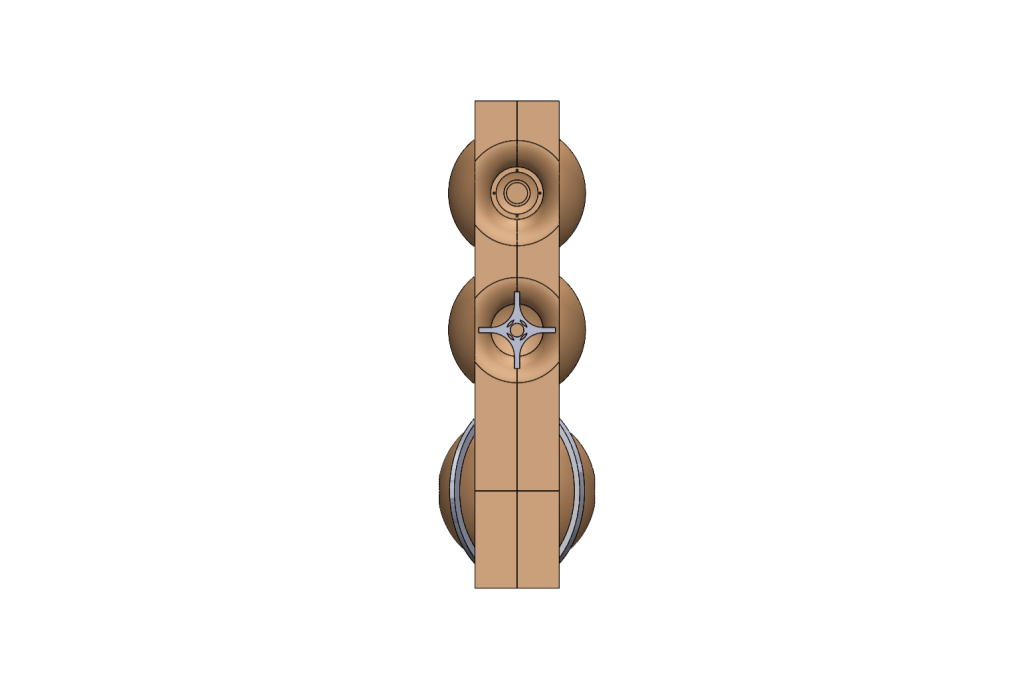

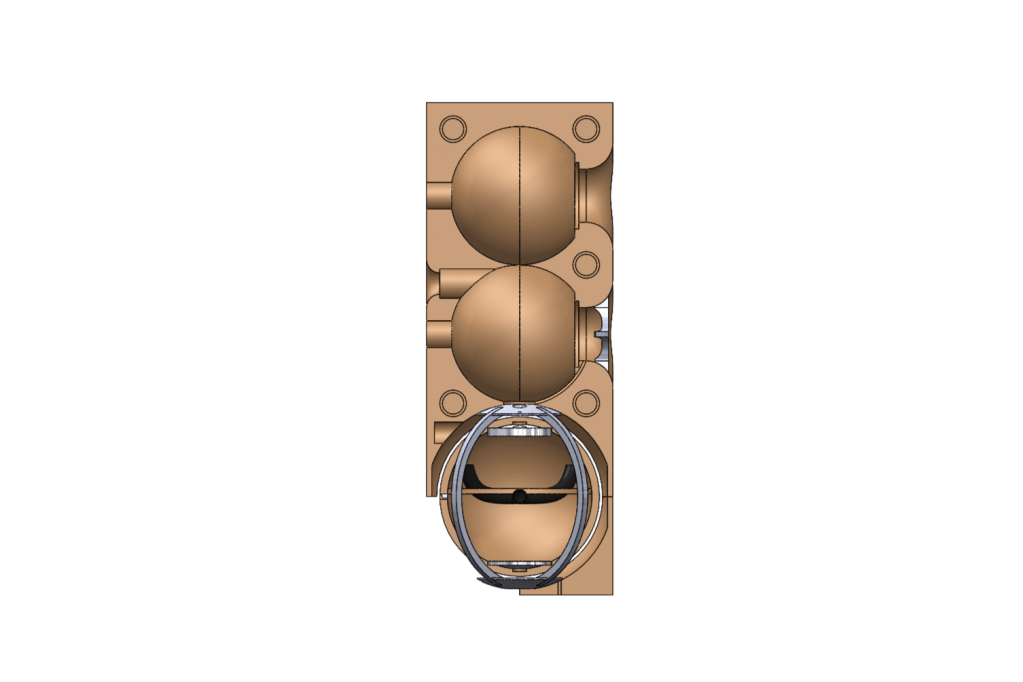

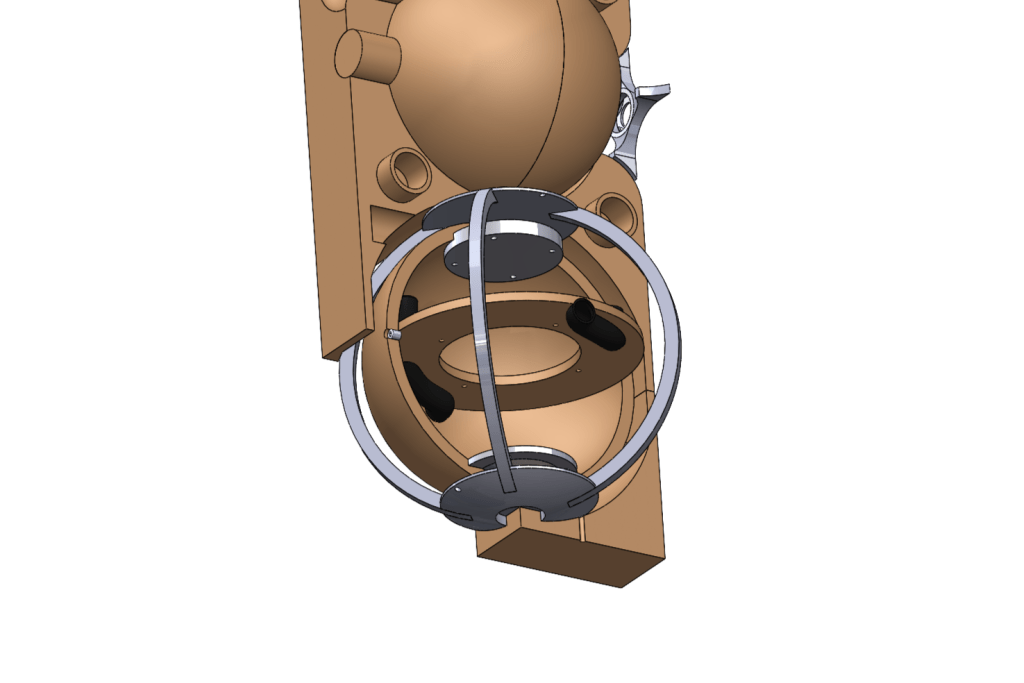

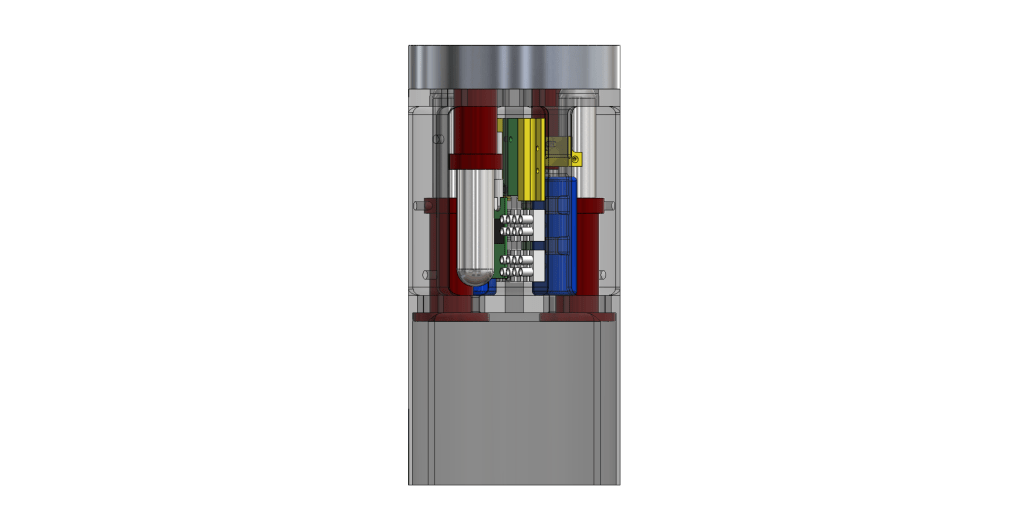

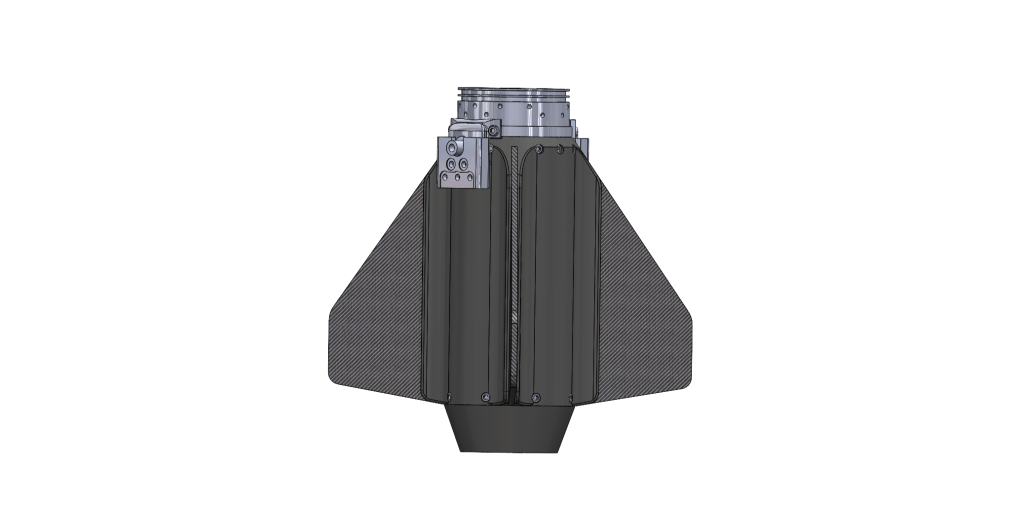

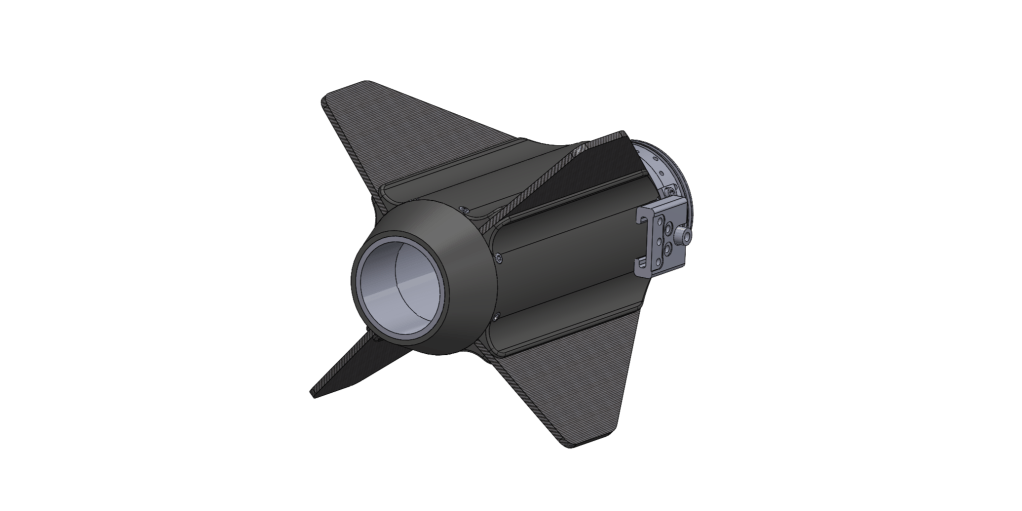

The fincan entailed a different challenge; how to manufacture a thin walled part, and constrain it, from the heads of bolts alone, while assembly required this is the final component of installation.

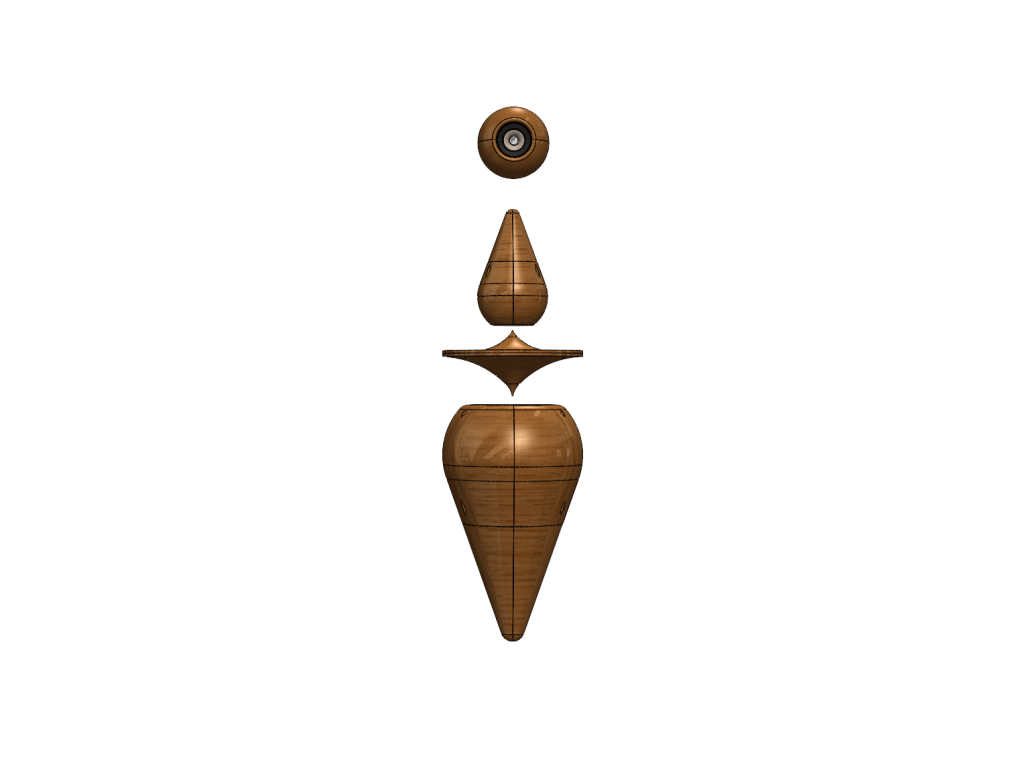

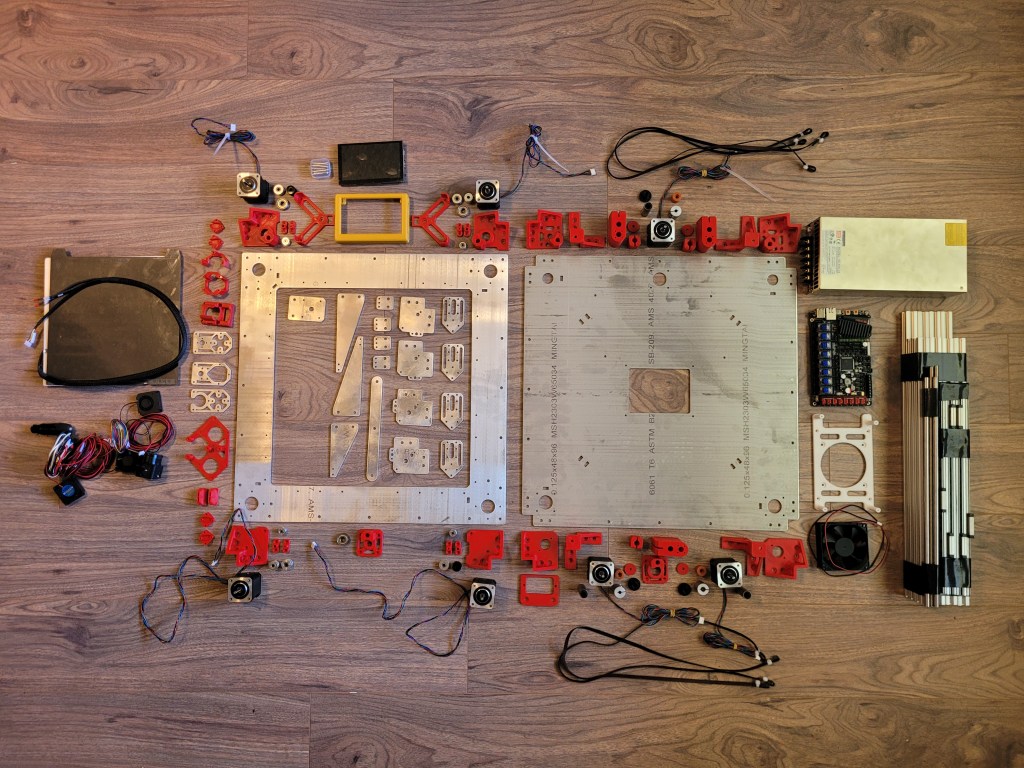

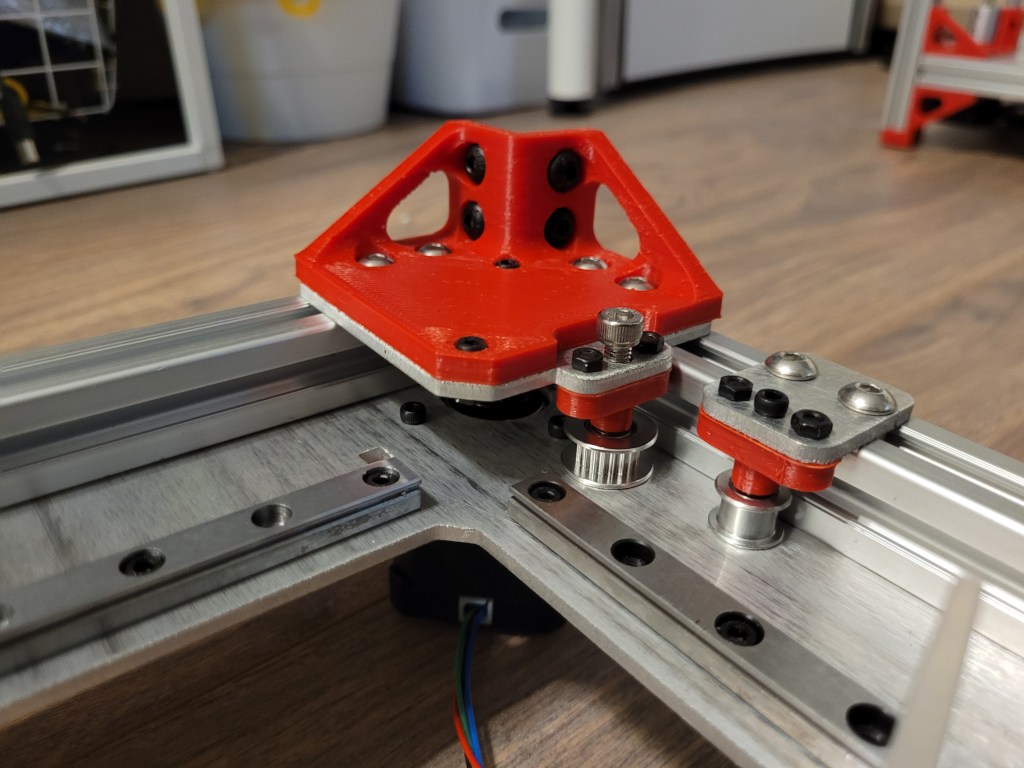

Two design concepts were made; one as a single piece, and another, shown below, with concentrically aligned portions (the inner section is constrained from the bolt heads and follows the boat tail geometry, and the outer section holds the finds and is epoxied to the inner while resting on a rear lip)

Both these designs saw multiple revisons, and as shared, the fincan has two parralel concepts, but both were designed in 3 days total (during 3 evenings after my internship).

Although speed is not the primary goal in engineering, I thrive when high-stakes challenges are presented, or I create that tone within personal goals. This allows more time in Conceptualization and Ideation, while CAD and Manufacturing delivers fast prototyping.